Author Mr. Pulkit Jain / Date: 25 Jul, 2025

Recycled Yarn

Recycled yarn is not just a trend—it’s a necessary change for a greener future. It helps reduce pollution, saves resources, and supports ethical fashion.

Whether you’re a textile manufacturer, fashion brand, or hobby crafter, choosing recycled yarn is a smart step toward sustainability. Support eco-friendly choices, and help the textile world become more responsible.

What is Recycled Yarn?

Recycled yarn is yarn made by reusing old materials instead of using new raw fibers. It’s a smart and sustainable way to make textiles.

These yarns are created from:

1- Textile waste like fabric scraps from factories

2- Used garments that are no longer wearable

3- PET plastic bottles (used mostly for recycled polyester)

How is it made?

The process starts by collecting used materials. These materials are cleaned, broken down into fibers, and then spun into new yarns. This method gives waste a new life and reduces the need for new resources.

Why Recycled Yarn Matters Today

1. Traditional Yarn Harms the Environment : Producing yarn from virgin cotton or polyester uses a lot of water, energy, and chemicals. It also causes air and water pollution.

2. Reduces Waste : Every year, tons of textile waste end up in landfills. Recycled yarn helps reduce this by reusing that waste.

3. Promotes Circular Fashion : Instead of throwing clothes away, recycled yarn supports circular fashion, where old materials are reused again and again. This helps in building a more sustainable future.

Types of Recycled Yarn

1- Recycled Cotton Yarn : Made from discarded cotton clothes or factory waste. It's soft and breathable and used in t-shirts, socks, and home textiles.

2- Recycled Polyester Yarn : Created from PET bottles or old polyester garments. It’s durable, moisture-wicking, and used widely in sportswear and jackets.

3- Recycled Wool Yarn : Produced by shredding old woolen garments. It’s warm and commonly used in sweaters, scarves, and blankets.

4- Blended Recycled Yarn (Cotton + Polyester) : Combines recycled cotton and polyester for strength and softness. Perfect for casual wear and home textiles.

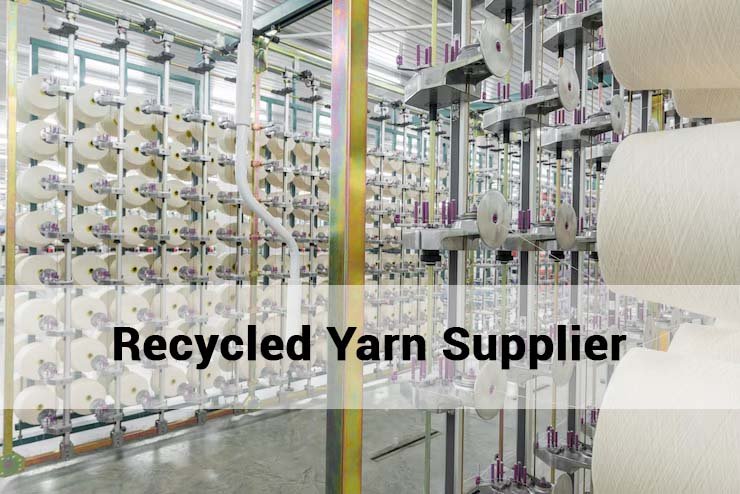

How Recycled Yarn is Made

Step-by-Step Process:

1- Collection: Used garments, textile waste, and PET bottles are gathered.

2- Sorting: Materials are sorted by color and fabric type.

3- Shredding: Items are shredded into fibers.

4- Spinning: Fibers are spun into yarn again.

5- Dyeing (optional): Some yarns are dyed if needed.

6- Winding & Packaging: Final yarn is prepared for use.

Mechanical vs. Chemical Recycling:

1- Mechanical Recycling: Breaks down material physically (no chemicals). Mostly used for cotton and wool.

2- Chemical Recycling: Dissolves and reprocesses materials at the molecular level. Common for polyester.

Certifications to Look For:

1- GRS (Global Recycled Standard)

2- OEKO-TEX® These ensure the yarn is truly recycled and safe for use.

Benefits of Using Recycled Yarn

Saves water and energy: Recycled cotton uses up to 90% less water than virgin cotton.

Less waste: Keeps plastic and fabrics out of oceans and landfills.

Reduces carbon footprint: Less energy means fewer emissions.

Cost-effective: Often cheaper in bulk, especially for large textile orders.

Applications of Recycled Yarn

Recycled yarn is used across industries:

Fashion: T-shirts, jackets, scarves, jeans.

Home textiles: Cushion covers, rugs, bedsheets.

Industrial use: Car interiors, insulation fabrics.

Crafts: Knitting, crocheting, and handweaving projects.

Recycled Yarn vs Virgin Yarn

| Feature | Recycled Yarn | Virgin Yarn |

| Environmental Impact | Low | High |

| Water Use | Minimal | High (esp. cotton) |

| Cost (Bulk) |

Cost-effective |

Expensive |

| Durability | Slightly lower (in some cases) | High |

| Innovation | Growing rapidly | Mature technology |

How to Choose the Right Recycled Yarn Manufacturer

Key Factors to Consider:

Certifications: GRS, OEKO-TEX, ISO standards

Consistent Quality: Test samples first

MOQ (Minimum Order Quantity): Check if it suits your needs

Ethical Sourcing: Transparency in their supply chain

Questions to Ask:

1- What is the fiber content and blend?

2 - Is your yarn certified?

3- What is your production capacity and lead time?

4- Can I get samples?

Why it Matters:

Choosing a reliable supplier ensures consistent supply, better product quality, and support for long-term innovation.

Challenges in Recycled Yarn Adoption

1. Quality Concerns : Recycled fibers are sometimes shorter, making yarn slightly less durable.

2. Limited Supply : Raw material availability (like PET bottles or textile waste) can limit production.

3. Lack of Awareness : Many consumers are still not aware of recycled yarn or why it matter

Future of Recycled Yarn in the Textile Industry

Innovations on the Way:

Advanced chemical recycling methods

Use of AI and robotics in sorting waste

High-quality recycled yarns for technical and performance wear

Growing Demand

Big brands and designers are shifting to eco-friendly materials

Governments and regulations are pushing for sustainability

Why Recycled Yarn Is the Future of Textiles

Recycled yarn is made by reusing materials like old clothes, textile waste, and plastic bottles to create new yarn. It helps reduce pollution, saves water and energy, and supports sustainable fashion. Common types include recycled cotton, polyester, wool, and blended yarns. Used in clothing, home textiles, and crafts, recycled yarn is eco-friendly and cost-effective. As demand grows and technology improves, recycled yarn is shaping the future of the textile industry.