Ravi Kumar / Date: 19 Aug, 2025

Recycled Yarn - Solutions for a Greener Textile Future

The textile industry is one of the largest contributors to global pollution, consuming massive amounts of water, energy, and raw materials. Every year, millions of tons of textile waste and plastic end up in landfills or oceans, creating serious environmental challenges. Recycled yarnoffers a sustainable solution by turning waste materials into valuable fibers for fabric manufacturing.

Companies like RG Fibers (RG Yarn)one of the leading recycled yarn manufacturers in India, are proving that sustainable practices can go hand in hand with quality production. By collecting, sorting, and processing textile waste, they create durable recycled fiber yarn that supports both businesses and the environment.

In this article, we’ll explore the science, process, benefits, and innovations behind recycled yarn production, along with insights into how companies like RG Yarn are shaping the future of the textile industry.

Recycled Yarn: Sustainable Solutions for Fabric Manufacturers

So, what is recycled yarn? In simple words, it’s yarn made by recycling yarn waste, plastic bottles, old textiles, and post-production scraps into new, usable fibers. Instead of letting waste end up in landfills, recycling yarn gives a second life to materials that would otherwise be discarded.

Textile manufacturers use recycled yarn for making fabrics in fashion, home textiles, upholstery, mattresses, and even industrial applications. By partnering with a recycled yarn supplier brands can cut costs, reduce carbon footprint, and appeal to eco-conscious consumers.

Common sources of recycled yarn include:

- Recycled yarn from textiles (old clothes, fabric scraps, post-consumer garments)

- Recycled yarn from plastic bottles (PET bottles converted into polyester yarns)

- Recycled fiber yarn from ocean plastics (through cleanup initiatives like SEAQUAL)

- Recycled yarn from denim and cotton waste

This growing trend is not just a green choice – it’s a smart business move.

Benefits of Recycled Yarn

Switching from virgin materials to recycled yarn offers multiple advantages:

- Reduces landfill pressure – Textile and plastic waste are repurposed instead of being dumped.

- Saves water and energy – Recycled yarn production consumes significantly less water compared to virgin cotton or polyester.

- Reduces carbon footprints - Virgin material processing is avoided; thus, emissions on greenhouse gases are reduced tremendously.

- Cost-effective sourcing – Manufacturers save on raw material costs by using waste-based inputs.

- Supports circular economy – Waste is not the end product but the starting point for new manufacturing.

- Strong consumer appeal – Today’s buyers prefer eco-friendly fabrics, giving brands a marketing edge.

The Environmental Impact of Recycled Yarn

To understand the impact, let’s compare recycled yarn with virgin yarn:

- Virgin cotton requires thousands of liters of water per kilogram. Recycled cotton yarn needs almost no extra water since it comes from existing fabric waste.

- Virgin polyester is oil-based and energy-intensive. Recycled polyester yarn (from PET bottles) reduces energy use by nearly 50% and lowers emissions.

- Yarn recovery and recycling prevents millions of tons of waste from entering oceans and landfills each year.

According to recent industry studies, if textile manufacturers globally adopt recycling yarn practices the industry could cut its carbon footprint by up to 30%. That’s a massive win for the planet.

Recycled Yarn vs Virgin Yarn

| Factor | Virgin Yarn | Recycled Yarn |

| Raw Material Source | Cotton fields, oil-based polyester | Waste textiles, plastic bottles, denim, cotton |

| Environmental Impact | High water, chemical, and energy use | Lower carbon footprint, less water and energy |

| Cost | Expensive due to raw materials | More cost-effective (waste re-used) |

| Durability | Strong and consistent | High-quality (comparable with virgin in many cases) |

| Sustainability | Limited | Contributes to circular economy |

This makes recycled yarn manufacturing a clear winner for sustainable fashion and textiles.

Characteristics of Recycled Yarn

Every recycled fiber yarn has unique properties depending on the waste source:

- Recycled cotton yarn – Soft, breathable, ideal for clothing and bedding.

- Recycled polyester yarn – Strong, durable, resistant to stretching/shrinking.

- Recycled denim yarn – Naturally colored, eliminating dyeing needs, saving water.

- Recycled yarn from ocean plastics – Excellent strength, often used in outdoor and upholstery fabrics.

Thanks to innovations in yarn recovery and recycling, the performance of recycled yarn today is almost identical to virgin yarn.

Science of Recycled Yarn: Durability, Strength and Performance

One common concern is whether recycled yarn is as good as virgin yarn. It is yes correct-proper production of recycled yarns, means that durability and performance are not compromised. Modern processes such as chemical recycling, dope dyeing, and combing help remove impurities, improve fiber length, and enhance yarn quality. For instance, mechanically recycled cotton blends may have shorter fibers, but when combined with virgin cotton and processed through combing, the yarn becomes smooth, durable, and versatile.

This ensures recycled yarn meets the same strength and softness standards required in the textile industry.

Recycled Yarn Made from Post-Consumer Textile Waste

Textile waste is one of the biggest contributors to pollution. By collecting post-consumer waste like old garments and leftover scraps, recycling yarn helps recover valuable fibers.

The process includes:

- Collection & Sorting – Waste is sorted by color and fiber type.

- Shredding & Cleaning – Fabrics are shredded into fibers and cleaned.

- Blending – Recycled fibers are blended with other fibers (e.g., PET for strength).

- Spinning – The fibers are spun into recycled yarn for new textile production.

This process not only reduces waste but also supports yarn recovery and recycling at a massive scale.

Innovation in Recycling

Recycling technology is evolving rapidly. Some key innovations include:

- Dope-dyeing of recycled polyester yarn- Adding color during fiber creation, eliminating harmful dyeing processes.

- Recycled cotton combing process -Promotes fiber length and yarn strength.

- Chemical recycling of polyester waste – Produces recycled yarn with quality equal to virgin polyester.

- Blending innovations – Mixing recycled fibers with virgin fibers for enhanced durability.

These innovations are driving the growth of recycled yarn manufacturing worldwide.

How Combing Enhances Recycled Yarn Quality

One challenge in recycling yarn is the short fiber length in waste textiles. Combing helps solve this issue by:

- Removing short fibers and impurities.

- Producing smoother, stronger yarn.

- Allowing higher blends of recycled content without compromising quality.

Studies show that recycled cotton yarn blends, when combed, achieve better durability than even some virgin cotton samples.

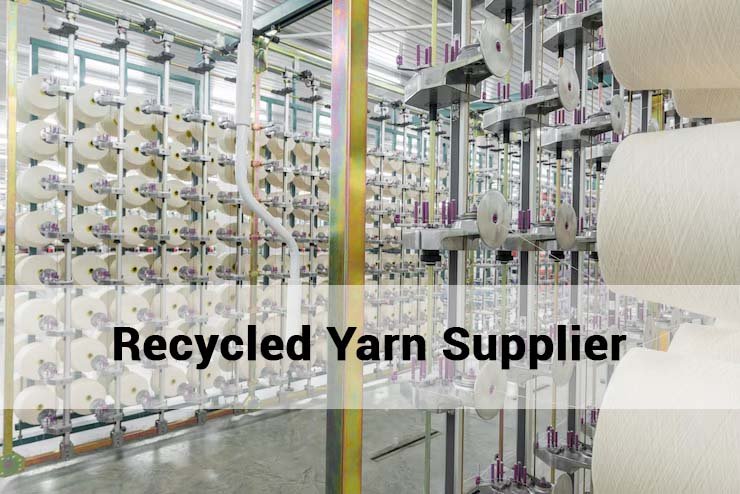

Largest Manufacturers in India for Recycled Yarn – RG Fibers

When it comes to recycled yarn manufacturers in India RG Fibers (RG Yarn) is a trusted leader. With multiple dedicated recycling units, they specialize in recycled yarn production using a wide variety of waste materials.

Why RG Fibers Stand Out:

- 5+ dedicated recycling units across India.

- Process involves collection, sorting, shredding, blending, and spinning without using water.

- Produces yarn using 80% recycled yarn and 20% PET fiber for strength.

- Supplies to leading textile industries worldwide.

- Recognized as a top recycled yarn supplier with consistent quality.

By focusing on recycled yarn from textiles and plastics, RG Fiber contributes significantly to India’s circular textile economy.

Everything You Need to Know About Recycled Yarn

The recycled colored yarn is a common phrase in the industrial sphere of textiles. Theigwake (conscious textile manufacturing firms in India) focus on the use of recycled yarns and concentrate their energies in the production of the same. Yarn production with a type of yarn which makes use of raw materials belonging to various recyclable materials is all about this type. All the useful and gratifying methods to recycle something old into something new happen to be picked up by the textile owners.

One can recycle several types of materials: one of them is clothing waste. This has been used to turn such items into other things. They were spun into rags to be used as cloths, snatched and cut into stripes as a rugging yarn, as well as in yarn. This recycling process was only recently when due to the culture of convenience which is clearly dominant in the western world has reduced this practice. Due to this philosophy of throwing them in the trash and buying a new one, there has been the tremendous issue of waste that has become a giant in all environmental issues.

Conclusion: A Smarter Future with Recycled Yarn

The demand for sustainable textiles is growing worldwide. By embracing recycling yarn technologies, fabric manufacturers can lower costs, reduce pollution, and meet consumer expectations for eco-friendly products.

Companies like RG Fibers leading recycled yarn manufacturers in India, are showing how innovation and responsibility can transform the textile sector. Whether it’s recycled yarn from textiles, PET bottles, or cotton waste, the future of the textile industry lies in smart, sustainable solutions.

If you are a business looking for a reliable recycled yarn supplier, consider working with RG Yarn – where sustainability meets quality.